Creating a Safety Buffer with INTELLO

When you drive, do you tailgate the car in front of you or do you leave a safety buffer? Although you are very unlikely to crash, do you bother putting on a seat belt? Do you increase your safety buffer as you drive faster? Like safe driving, as insulation levels rise, we want to increase drying reserves. Like properly installed airbags, INTELLO PLUS and INTELLO X membranes have a uniquely strong ability to increase the safety buffer (aka the drying reserve).

475 provides the INTELLO PLUS and INTELLO X membranes, both have the same high level of airtightness and smart vapor control. To learn about the differences between INTELLO PLUS and INTELLO X membranes see this video.

Increase Safety with INTELLO PLUS & INTELLO X membranes

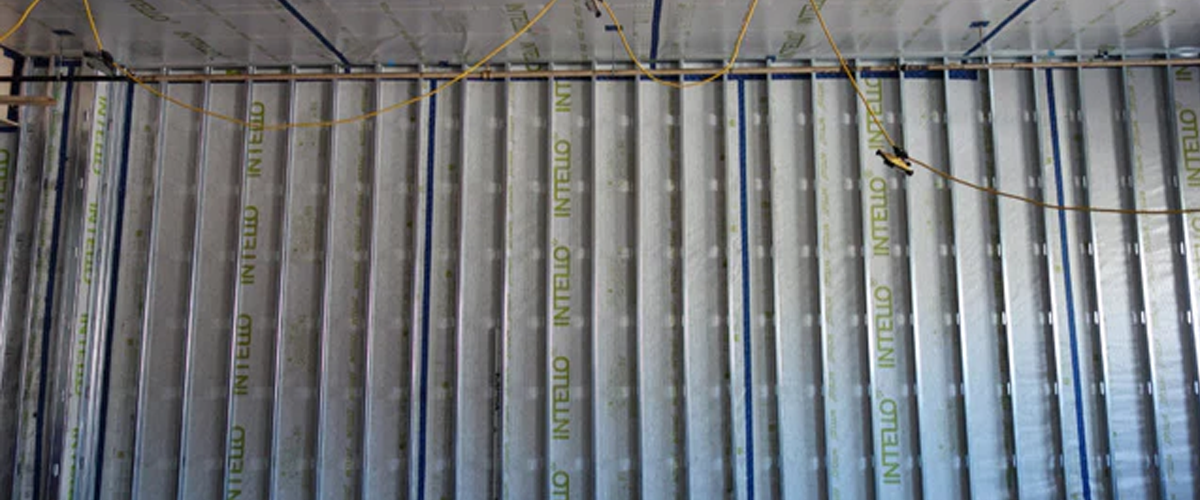

INTELLO PLUS Installation

You want to build a well insulated high-performance building, even possibly achieving Passive House levels. You might be located in Vermont or Maryland. You're looking for the right tools to mitigate risks and do it safely. In many circumstances the INTELLO PLUS and INTELLO X humidity dependent vapor retarding membranes just might be the perfect tool. Why? Two reasons:

-

First, the INTELLO membrane is a first class air barrier and it gets installed in the best place, inboard of the insulation - keeping the conditioned air in the conditioned space - providing durable airtightness. (See An Interior Air Barrier Does It Better)

-

Second, INTELLO membrane is the best vapor retarder on the market. It is an intelligent vapor variable membrane - a smart vapor retarder. If you're in a location with a winter season, INTELLO works to increase drying reserves of your assembly and prevent moisture damage risk by limiting wetting in the winter and allowing drying inward in the summer. (See Why the Vapor Curve Matters)

Generally speaking, the INTELLO membrane decreases risk, achieving safety. However, there are two exceptions:

-

When you have a constant high humidity interior climate, like indoor swimming pool, or commercial kitchen a vapor retarder such as CONSTIVAP should be installed inboard AND suchassemblies should be able to dry outward through vented rainscreen or roofs - See also 475 Video: Sauna Uses Solitex Fronta Quattro and DA)

-

When the building is located in Climate Zone 1 - 3A an outboard airtight class III vapor retarder makes for dryer/more forgiving assembly. Use Pro Clima SOLITEX ADHERO 3000.

Airtightness is good in any climate - and ideally protected from the elements/thermal cycling, located inboard of the insulation. Make sure you blower door your building and confirm your airtightness.

And the benefits of smart vapor variability increase:

-

as insulation levels increase

-

as the winters get stronger

-

as the outboard construction gets more vapor closed

-

when the insulation is not hygroscopic

-

when the structure gets wet during construction

Example Assembly

There are an infinite number of enclosure assembly types and each one must be considered on its own merits - its risks, its costs, its durability. And depending on what climate you are in, the assembly make-up can be greatly affected. (See Foam-Free Wall Assembly Guidelines by Climate Zone) One must also consider use of the building, exposure, solar radiation and more. It's complicated. But as we will show, with the INTELLO PLUS and INTELLO X membrane it is almost impossible to do harm

In this post, to demonstrate the basic truths about the INTELLO PLUS and INTELLO X membranes listed above, we'll look at the humble double-stud wall, a cost effective mainstay of high-performance and Passive House construction. (see: The Double-Stud Wall Simplified: Low Cost, High Performance)

The construction, from outside to inside is often:

-

Back-vented rainscreen siding

-

Vapor open WRB SOLITEX MENTO 1000

-

1/2" Plywood sheathing

-

10" densepack cellulose insulation (~R 3.5 / inch)

-

INTELLO PLUS membrane

-

Gypsum board

Risks

In this classic configuration, there is concern that the sheathing, the plywood, might get too wet -which can cause structural degradation/rot or mold formation.

How do we assess risk? Like assessing climate change risks or car crash risks, we run simulations. In this case we use WUFI Pro. Like other simulations WUFI Pro will not give predictions with 100% certainty - but it is very good at helping assess relative risk. Is this riskier than that? What are the variables? What happens when we adjust variables. Is there a safety buffer in the results? WUFI Pro is our crash test.

To avoid mold damages we generally like to see test results regarding two things: Moisture Content % and Relative Humidity Levels.

-

Moisture content risk - There is much debate about what the upper absolute safe limits are. Hunt and Garret, 1938 and Viitanen 1996 indicate that maintaining wood moisture content below 20% completely inhibits fungal development. Section R802.1.5.10 of the building code goes as far to say that fire-retardant-treated wood shall be dried to a moisture content of 19 percent or less for lumber and 15 percent or less for wood structural panels before use.

-

Mold Growth - ASHRAE Standard 160 uses a dynamic mold index to assess risk based on surface temperature, relative humidity, and material sensitivity. Instead of a fixed humidity threshold, the model calculates critical RH levels that vary by substrate. Mold growth risk increases when a 30-day average RH nears these levels. Mold index ≥3 indicates visible growth; mold <1 is typically not detectable.

Naturally, each measurement of risk is related to the other. 80% RH on the surface of plywood for some time during a cold spell corresponds to moisture content of 20% of the same sheathing. Below we're looking at the moisture content of the interior side of the plywood sheathing as it accounts for some buffering of the moisture in the board and is a widely used proxy for avoiding issues in wood framed walls.

Example Locations

So given all this, let's take a look at this example assembly in various locations: Burlington, Chicago, Boston, Philadelphia, and Baltimore (climate zones 6A, 5A, & 4A). Let's verify the basic premise that INTELLO PLUS and INTELLO X membranes help build drying reserves, and where we have a winter and summer it poses no risk, and makes for safer assemblies, when compared to the same wall without this smart vapor retarder.

These WUFI Pro models are comparing the assembly with and without INTELLO PLUS, but both versions include gypsum board on the interior of the insulation. Gypsum board’s material is airtight (while the install is rarely airtight) so within the model all versions have an interior air barrier. The dramatic change in the plywood’s moisture content is rooted in the vapor variability of the INTELLO and not the airtightness.

All of these example assemblies that did not include INTELLO PLUS showed a “Yellow” signal light for the interior side of the plywood’s mold growth risk assessment (per ASHRAE 160P standard). This “Yellow” classification means it’s a ASHRAE 160 mold index from 1 to 3 and additional criteria or investigations are needed for assessing acceptability. When these same assemblies included INTELLO PLUS the interior side of the plywood’s mold growth risk assessment is “Green” which means an ASHRAE 160 mold index up to 1 and is usually acceptable. WUFI Mould Index VTT 2.1 was used for this assessment.

The following graphs are looking at the plywood’s moisture content (shown on the vertical axis) over 10 years (shown on the horizontal axis). Blue colored lines indicate that the assembly does not include the INTELLO PLUS membrane on the interior and the green colored lines indicate that the assembly includes the INTELLO PLUS membrane. All assemblies started off with doubled moisture content of the materials and modeled with ASHRAE Year 2 climate data for the location. The modeled assemblies are, from outside to inside:

-

Back-vented rainscreen siding

-

Vapor open WRB SOLITEX MENTO 1000

-

1/2" Plywood sheathing

-

10" densepack cellulose insulation (~R 3.5 / inch)

-

INTELLO PLUS membrane

-

Gypsum board

All of the models used the same materials and thickness of materials – only the climate data and the inclusion of INTELLO is adjusted between the models. Each graph includes a red line at 18% MC.

Burlington, VT, USA

Burlington, VT, USA is in Climate Zone 6A. The assembly without INTELLO (shown in blue) is consistently peaking above 18% moisture content, but when INTELLO is included in the assembly (shown in green) the plywood moisture content stays below 18%. In its moisture content equilibrium the plywood without INTELLO consistently peaks at 21% MC and the plywood with INTELLO consistently peaks at 16.2% MC.

Chicago, IL, USA

Chicago, IL, USA is in Climate Zone 5A. The assembly without INTELLO (shown in blue) is consistently peaking above 18% moisture content, but when INTELLO is included in the assembly (shown in green) the plywood moisture content stays below 18%. In its moisture content equilibrium the plywood without INTELLO consistently peaks at 19.8% MC and the plywood with INTELLO consistently peaks at 15% MC.

Boston, MA, USA

Boston, MA, USA is in Climate Zone 5A. The assembly without INTELLO (shown in blue) is consistently peaking above 18% moisture content, but when INTELLO is included in the assembly (shown in green) the plywood moisture content stays below 18%. In its moisture content equilibrium the plywood without INTELLO consistently peaks at 19.6% MC and the plywood with INTELLO consistently peaks at 15.8% MC.

Philadelphia, PA, USA

Philadelphia, PA, USA is in Climate Zone 4A. The assembly without INTELLO (shown in blue) is consistently peaking above 18% moisture content, but when INTELLO is included in the assembly (shown in green) the plywood moisture content stays below 18%. In its moisture content equilibrium the plywood without INTELLO consistently peaks at 20.8% MC and the plywood with INTELLO consistently peaks at 16% MC.

Baltimore, MD, USA

Baltimore, MD, USA is in Climate Zone 4A.Both assembly options stay below 18% MC showing the importance of an interior air barrier, but the risk is reduced further by using the smart vapor retarder INTELLO PLUS (shown in green). In its moisture content equilibrium the plywood without INTELLO (shown in blue) consistently peaks at 17.5% MC and the plywood with INTELLO (shown in green) consistently peaks at 14.2% MC.

Conclusion

As we increase insulation levels and performance expectations, the INTELLO PLUS and INTELLO x membranes not only offer great airtight control but also powerful protection from moisture damages. If you are working on a high-performance project we are very happy to look at your assembly specifics and help determine what can be the most cost effective and durable solution. Please ask us.

Drive safe. Build safe.

See the Canadian version of this blog post for Canadian city examples.