Buildings move. Ensuring that your air barrier is resilient to movement is crucial to ensuring the longevity and performance of your building.

Unless you're building a structure using just one material (like superadobe), your building will consist of an array of different materials. In response to fluctuations in temperature and humidity, different materials expand and contract at distinct rates. Buildings also settle over time, which can put strain on junctures between different materials – to say nothing of the small geological events that buildings must be able to withstand in certain parts of the world. As buildings move, the transitions between materials become likely sites of cracks. And because a continuous air barrier is paramount in ensuring building performance, it's important to select materials that are resilient to this inevitable movement.

Caulk dries and cracks over time, and so fails as an air seal at the junctures between building components.

Many of the traditional foams and caulks used at these joints perform very poorly at ensuring airtightness over time. These materials may dry brittle, making them highly prone to cracking. The chemical reaction that enables them to dry continues over time, and so these materials keep shrinking – meaning that they are likely to crack even if fluctuations in environmental conditions didn't occur – and no matter where your building is constructed, there's going to be weather. These junctures are some of the most challenging places to ensure airtightness to begin with – so when we select materials that are incapable of moving with the building, we increase the likelihood of a compromised air barrier even further. Putting low-performing materials in some of the most sensitive places in buildings is almost a guarantee that building performance will decline over time, and all of the problems associated with a compromised air barrier – moisture loading of the assembly, mold and rot, air leakage, occupant discomfort – will follow.

To ensure that the air barrier is resilient to building movement and remains robust over time, it is important to select materials that both strong and flexible at the places where different materials meet. Connecting windows to bucks and sills, flooring to slab, and wooden joists to masonry all require thoughtful planning to ensure that as these materials move and shift over time, the connections between them stay tight. As an extreme example of building movement and great test of material integrity, tiny houses are constructed on axels and driven on highways, which is like subjecting the building to a sustained earthquake. We've heard examples from customers that just one highway trip is enough to shatter a foam or caulk connection. Fortunately, an array of materials that are both flexible and airtight exist, and we describe a few of these below to help you ensure that your air barrier remains continuous even as your building moves and shifts over time.

Flexible Tapes: A Resilient Alternative

Take a walk around your home or office, and look for cracks in the interior of the building. More than likely, you'll be able to find quite a few where materials meet: at doorways, around windows, and where the floor meets the wall and ceiling. These are also some of the most likely places to have been caulked or spray foamed. Because caulk and foam continue to shrink over time, they're highly prone to cracking – and may well account for the gaps that you're looking at.

Pro Clima tapes don't tear when exposed shear due to shifts in the building. A shift of over 1.5cm is shown in these images.

Flexible tapes and adhesives are great alternatives for sealing these transition points while also ensuring flexibility and resiliency over time. We love Pro Clima tapes, which are designed to withstand building movement and while remaining strongly adhered and highly airtight. TESCON Vana is a highly versatile tape capable of handling both interior and exterior applications, ranging from connecting the junctures between exterior sheathing to ensuring continuity between the interior air barrier and window frames. Unlike caulk, Pro Clima tapes can handle shear movement over time without compromising airtightness, ensuring that as the building moves, the air barrier remains robust and intact.

Flexible Adhesives and Caulks: For Challenging Connections

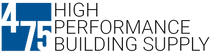

In this detail, CONTEGA HF is used to attach the Intello Plus interior air barrier to the concrete slab. Image from 475's 2X Framing E-book - available as a free download.

CONTEGA HF, strong enough to lift a brick, attaches well to uneven surfaces, filling in cracks and spaces to ensure airtightness. (Brick itself still leaks, and needs to be plastered or otherwise air sealed.)

Although TESCON Vana is highly versatile, and a variety of more specialized Pro Clima tapes are available as well, there are times when using caulk adhesive makes more sense than taping because:

- it's more cost effective per linear foot than taping;

- it adheres well to uneven surfaces, filling in cracks and irregularities and ensuring continuous airtightness; and

- it allows for a “looser” connection between the interior barrier and the flooring, offering a buffer of flexibility during construction and throughout the lifetime of the building.

CONTEGA HF is an adhesive that never dries out or becomes brittle, ensuring that it is resilient to building movement. It also has the same vapor-variable properties as the INTELLO Plus interior membrane, ensuring good vapor performance and further increasing building longevity. Caulk is great for applications like attaching your interior membrane to the floor slab. Take a closer look at CONTEGA adhesives.

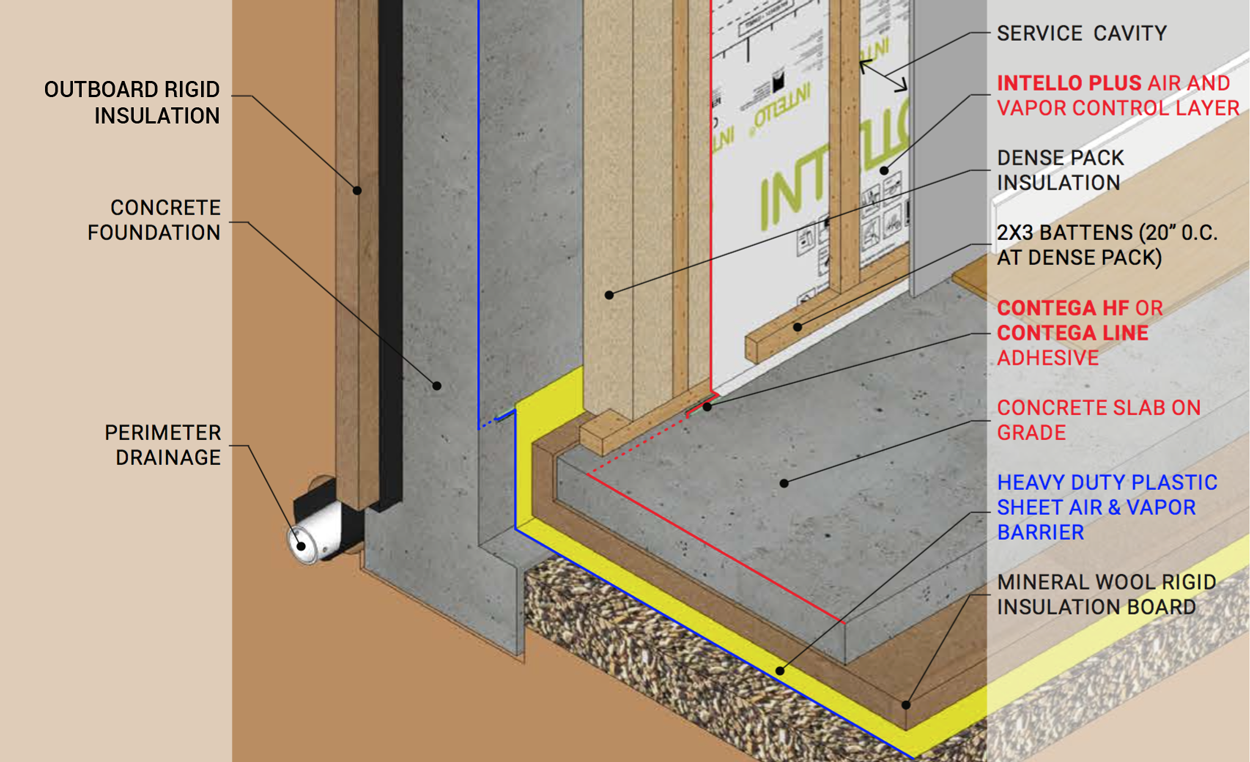

There are a number of techniques and approaches to effectively ensure that window frames are continuously and air tightly sealed to the rest of the interior air barrier.

Other Best Practices

Whether choosing tape or caulk, there are a number of important “best practices” to keep in mind.

- Remember that dust and dirt are inherently unstable and uneven – so don't tape to them. Make sure that your surface is clean before attempting to caulk or tape it.

- For uneven surfaces or junctions, especially at sites where wood and masonry meet, it may be important to prime the surface with TESCON primer to ensure a good air seal when applying caulk or tape.

- At complex junctions like windows, good sequencing is important: preparing tape corners and pre-taping any non-airtight spaces will ensure continuity and effectiveness of your air barrier.

The ROFLEX gasket allows for an airtight but flexible seal around planned penetrations into the air barrier. The gasket can be sealed with TESCON Vana tape to the rest of the assembly to ensure continuity.

Flexible tapes and adhesives help with other building challenges as well. Utilities require planned penetrations of your air barrier; electricity, water, sewage, HRV, and any other services necessarily require a hole in your airtight layer. Pro Clima tapes and adhesives, in conjunction with flexible gaskets, can also help you with these planned penetrations into your air barrier.

Building movement is a challenge, but with smart planning and the use of the right materials, there's no reason your air barrier won't remain robust and high-performing for many decades after construction.