New Mold Growth Index and Safe Double-Stud Walls

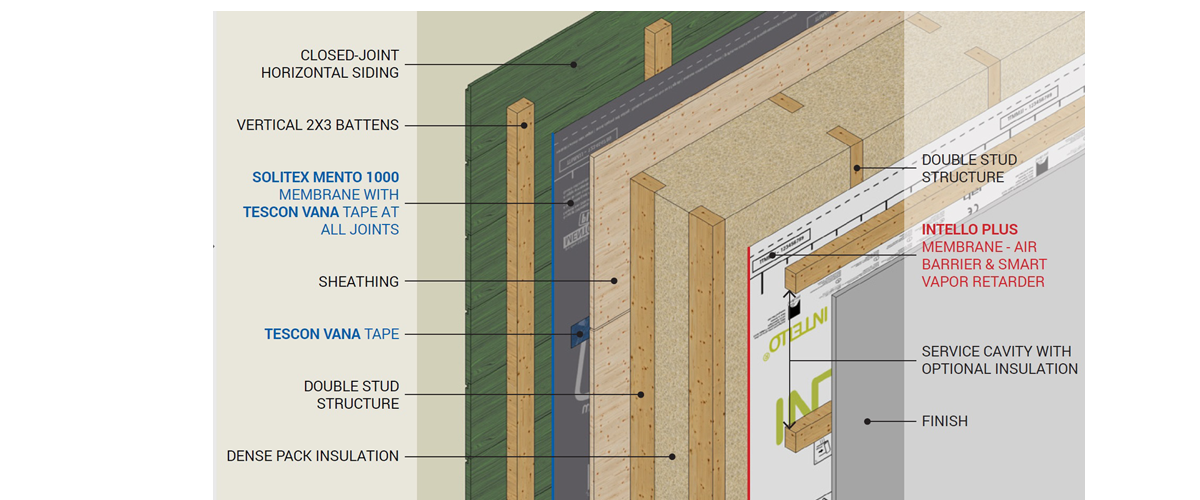

Double-stud walls have been regarded as a simple to build, low-cost, high-performance solution since the energy crisis in the 1970's. (See our blog post The Double-Stud Wall Simplified: Low-Cost High Performance, and free CAD details) Pack them right, meaning 3.8 to 4.2 lbs/cubic foot of cellulose, 2.5 lbs/cf for fiberglass or wood fiber - and as Jesse Thompson of Kaplan Thompson Architects presented at BuildingEnergy 17, as a minimum requirement, add a vented rain screen so they have a chance to dry outward.

Since we want to build these walls as economically as possible - when does adding INTELLO Plus

make sense to maintain acceptable risk?

What's Acceptable Risk?

In Monitoring of Double-Stud Wall Moisture Conditions in the Northeast, Building Science Corporation (BSC) reported on a study of double-stud wall in Massachusetts without vapor control (ie only painted gypsum board). The study lasted for 3 years, which included 1 year when the building was unoccupied. It did show that with healthy Relative Humidity (RH) on the interior (40-50%) that the wall Moisture Content in all walls, insulated with foam and cellulose, were showing condensation. In the subsequent year, while this occupied, not-super-airtight house had a continuous exhaust fan running, and with very low interior RH as a result (20%s) - and the north-facing cellulose wall still showed MC over 20%. In the conclusion Kohta Ueno writes:

ASHRAE 160 criteria were applied to the monitored data; all walls failed (i.e., mold growth likely). However, when the walls were disassembled at the conclusion of the experiment, the sheathing and framing showed remarkably little evidence of wetting damage or mold growth. No visible mold growth was found, nor evidence of staining or water rundown. The damage was limited to some grain raise of the interior surface of the OSB at the cellulose wall, and corrosion of fasteners.

475 has also previously discussed moisture risk per the old ASHRAE 160 standard in double-stud walls with both fiberglass and cellulose - Keeping Sheathing Dry in High-R Double-Stud Walls - a WUFI Study and Drive Safe, Build Safe.

New ASHRAE 160 and the Mold Growth Index

ASHRAE 160 has since been updated. As stated by the USDA Forest Products Laboratory, Standard 160 has now:

...incorporated the “mold growth index,” first proposed by Viitanen and Ritschkoff (1991), which was used to quantify the amount of mold growth that occurs in laboratory tests under controlled temperature and humidity conditions. The mold growth index assigns an ordinal number between 0 (no growth) and 6 (very heavy and tight growth). The Viitanen model can calculate the mold growth index from outputs of hygrothermal simulations and incorporates time, surface temperature, surface relative humidity, and the material sensitivity class. Standard 160 now requires that the mold growth index, calculated from hygrothermal simulations, be less than 3 (the threshold for visible mold growth).

With this new and improved model, sheathing (plywood/OSB) is classified as medium sensitive to mold growth/damage and set threshold for Mold Growth Index (MGI) at 3. 475 asked Manfred Kehrer (WUFI developer /www.wufi.us) to run simulations based on this new criteria for five climates: Boston (5c), Baltimore (4c), Atlanta (3c), Miami (2c) and Seattle (4a). We used fiberglass on purpose as the lowest cost solution.

The graph above shows, that for all but Miami, the walls exceed the 3 MGI threshold without INTELLO in the first winter, and the walls never recover from getting damp. You can also see this when plotting M% of the OSB/insulation interface in Baltimore, it exceeds 18% for long stretches every winter (which is higher than we recommend) and even 20% which is the level where practically all building scientists would have concern. Shown in the graph below:

INTELLO Plus optimizes performance and insulation in double stud walls

With INTELLO Plus, these double-stud walls, with a vapor retarding exterior sheathing layer (OSB at 1-ish perms) covered with the SOLITEX MENTO actively vapor open WRB - lead to safe construction in all climate zones, and even make the Miami wall dryer (no more winter time cycling in climate zone 2).

This smart vapor retarder and air barrier also make sure that the wall performs as intended at it's R-40+ value, as it encapsulated the fibrous insulation with airtightness on all 6 sides.

Note that 4a climate zone (Marine) puts more stress on the assembly than even Climate zone 5 (Boston). This since the drying capability of the wall is reduces by the climate's humidity levels. This is shown in the graph below, in which even with INTELLO Plus and some assumed construction moisture, it takes more than a year for the assembly to get below 3 and could be considered safe. As BSC pointed out in their double-stud wall research - one or two years of elevated MC is okay, and might only lead to raised grain and minor rust on screws/nails - cycling through such moisture levels every winter could cause further deterioration and thus leaving out INTELLO in such double-stud walls, would be taking a short cut that you could regret after a number of years.