Stapling the membrane in place:

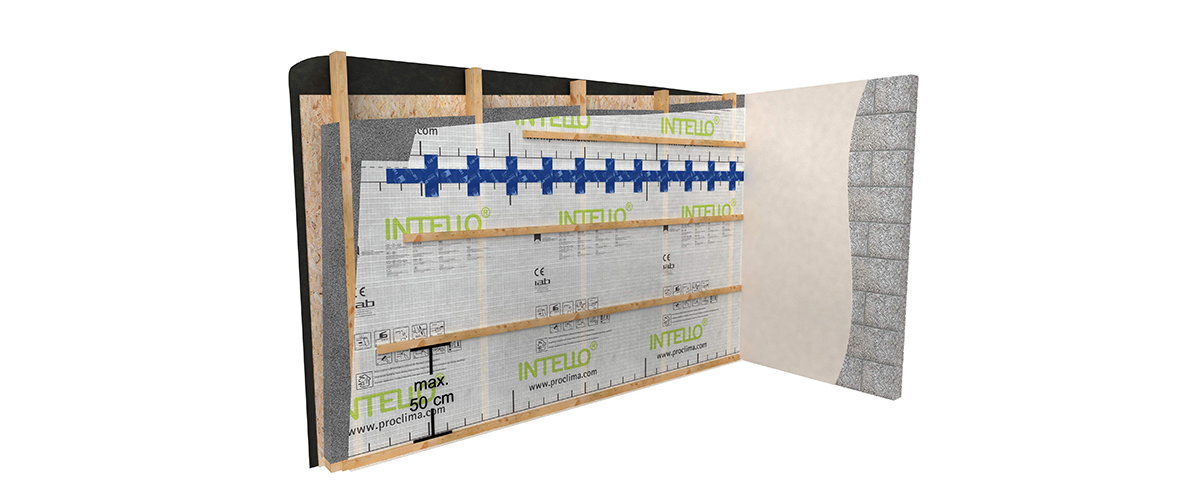

Unlike typical mesh used in most cellulose installations today, where staples are installed every 1/16", we recommend stapling INTELLO PLUS and INTELLO X every 2" (50 mm). For best tear resistance, apply staples parallel to the studs (see photo below). Use staples that measure at least 3/8" (10 mm) wide with 5/16" (8 mm) legs; T50 heavy-duty only. Otherwise, blow-outs may occur.

Staples parallel to studs - 2" on-center or less

-

Important note: While Pro Clima prints a 4" (100mm) staple spacing on the membrane, this is only appropriate when the cavity is already insulated with batts (cellulose, mineral wool, cotton, etc.)

-

Cap nails may also be used as an alternative, maximum 2.5" on-center spacing.

Plan for a maximum of 20” on-center for counter-batten spacing. Going beyond this increases tension on staple connections. In the case of wide spacing, closer staple spacing is required, and the importance of clean stapling increases. Staples must be flush with the studs and crooked or overdriven staples can compromise the seal.

Tape overlaps with TESCON VANA

Pro Clima adhesives are PSA tapes - meaning they must be pressurized to activate. Pressurize the TESCON VANA tape used to seal membrane seams with a PRESSFIX application tool. Next, apply horizontal counter-battens that are spaced maximum 20" on-center (for sheet rocking ease, 16" on-center works best) - this helps support the dense-pack, provides a gap for "bulging" and creates the all-important service cavity. If a taped membrane overlap is not directly supported by a battens, it is required to reinforce the seam with "stitch taping" - see also our installation guide. To do so - add perpendicular strips of TESCON VANA every 8-12" over the taped seam.

Large spacing (24" on-center) of the counter battening is not recommended. As this does increase the tension on the staple connections and requires the staple spacing to be even closer together and the importance of staples being flush with the studs increases (staples flush with the studs are also airtight, crooked staples are not...). The staples when using 24" on-center battens have a risk to pop and cause air leaks - the same is true for trying to dens-pack without counter battening. This is possible, but would require many more staples (1" on-center parallel with the studs), and you do need to roll the cellulose to enable sheetrock installation (bulges otherwise makes it impossible) - another option would be to use batt insulation in walls where counter battening is not possible.

Cellulose/Wood fiber installation:

It may seem counter-intuitive to cut additional holes in your airtight membrane, but when dense-packing insulation, it will be difficult for air to move the material properly if that air has nowhere to go. In other words, if you did a great job of airsealing the assembly, you must create a pathway for air to transport your insulation. To do this, cut a hole in your airtight membrane about half way up the bay void. This should give you sufficient room to move the tube all the way down in the cavity, but also assure you can dense pack the top to sufficient pressure. Additional 1.5" long air relief slits can be cut to help alleviate air pressure build up from blowing behind an airtight membrane. These air relief holes are taped over with TESCON VANA tape after the stud bay has been insulated.

Feed the hose through that hole to the bottom of the cavity and pull it back 10" (250mm). Start blowing the insulation, to make sure all corners in the bottom are filled, twist the tube 180 degrees (stiff tubes or "needles" are better for this purpose). Then work your way upwards, slowly packing the cavity to a density between 4.0 lbs/CF (65kg/m3) and 3.5lbs/CF (56kg/m3).

- Cut a hole approximately half way up the bay for the nozzle

- Add 1.5" long air relief slits approximately 8" from the top

- Additional slits can be made in bottom of bay and added in corners (as determined by installer - this depends on how airtight the outside of the building envelope is, etc)

- Insert the blowing tube and push it to the bottom of the cavity, then pull back ~10" (250mm) - dense pack the bottom of void.

- Now twist the tube 180° and start again at top of void. Reach all corners and begin dense-packing of void while working your way down.

- After insulation is installed, tape all holes with TESCON VANA, using ~6" (150mm) patches for the blow in X and regular TESCON VANA for the air relief slits

With experience, the installer can determine the density by the way it feels. Between 3 and 4 pounds per cubic foot, the feel of the installed material goes from soft (at 3 pounds) to actually hard at 4 pounds. At 3½ pounds per cubic foot, it will feel like a firm mattress. It really changes dramatically between 3 and 4 pounds.(56kg/m3 to 65kg/m3)

Inspect the insulation install to ensure a complete fill of the cavity. Once the dust has settled (there won't be much as INTELLO is airtight), make the membrane dust-free and apply ~6" patches of TESCON VANA over the blow-in holes (and any air relief holes) to reconstitute your airtight layer.

Patches like these are best done with ~6" squares of TESCON VANA 150. Cellulose dense packed in place at 3.5lbs/CF (56kg/m3) should self-support and stay properly packed after removing 'netting'. INTELLO Plus's translucency allows for visual inspection.

INTELLO PLUS, INTELLO X, and DB+ make the perfect choice for safe and consistent cellulose installation and quality control of cavity fills and cellulose density. Cellulose or wood fiber as the insulation material of choice, guarantees a perfectly gap free insulation layer and practically eliminates unwanted air movement behind the airtightness layer/within the insulation layer. If installed at the right density with counter battens, it is even slightly "spring-loaded" (when not rolled) and able to conform to the movement, shrinkage, settling and expansion of a wood-framed structure. The perfect base for the INTELLO to do its job!

Sheep wool, chopped straw (see video below), and other types of natural fibrous insulation insulation can also be dense-packed behind INTELLO PLUS, INTELLO X, and DB+ as an alternative to cellulose or wood fiber. Install density of the fibrous insulation varies depending on the type of insulation.

Sometimes insulation installers want to keep with their standard practices and prefer to blow insulation behind their typical support netting. Although this netting isn’t needed when using INTELLO PLUS, INTELLO X, and DB+ the netting does not affect the airtightness or vapor performance of these membranes. The airtight membrane can be installed over the insulation support netting without performance concerns.